19 Nov Warehouse-in-warehouse: Case Study Wasco

Warehouse-in-warehouse: Case Study Wasco

Answer to wide assortments, small orders and short response times

Globalization, sustainability, flexibilization of labor, big data, cloud computing, robotization, are all trends that have reshaped our business operations in the past decade. Yet there is one development that overshadows all these trends: the explosive growth of e-commerce.

Ten years ago, Wehkamp.nl was still the largest webshop in the Netherlands, V&D casually opened new stores, while a handful of tech nerds placed their first online orders via their brand new smartphones. The situation was virtually the same as in the 1990s, when Wehkamp, as a mail order company, led the way in distant sales and mobile phones were mainly used for making calls.

The rapid growth of e-commerce continued. It led to companies broadening their product ranges, opening multiple (digital) sales channels, placing smaller orders, having to deliver faster and having to cope with more extreme peaks in demand. The B2C market led the way, but the B2B market quickly followed. The impact on logistics was unprecedented. We crossed a tipping point. The best practices we knew were reaching their limits. We had to look for new tools and tricks.

Warehouse-in-warehouse

Nowadays it hardly takes any effort to add new items to your webshop. A wonderful business model, but those items all have to need a pick location in the warehouse. Warehouse-in-warehouse is a modern concept that allows you to pick efficiently from an expanding product assortment.

According to the divide-and-conquer principle, you divide your assortment into product groups. This can be done by segment, for example clothing, shoes and accessories, but also by logistical characteristics such as heavy/light, small/large/oversized, conveyable/non-conveyable, packaged/unpackaged or fast moving/slow moving. Which segmentations are smart differs per warehouse.

Each product group has its own zone in the warehouse, the warehouse-in-warehouse. Order pickers no longer have to walk through the entire warehouse, but limit themselves to a zone. That saves a lot of walking meters. Moreover, we can introduce the most suitable working method per zone. Perhaps a mechanized system is most suitable for the conveyables, while we continue to collect the non-conveyables by hand.

Wasco

Wasco is a leading wholesaler in the installation industry. Wasco’s distribution center in Apeldoorn provides an interesting case study in the application of modern best practices. Large goods are stored in the Apeldoorn DC, while Wasco has its small items in a mechanized DC in Twello.

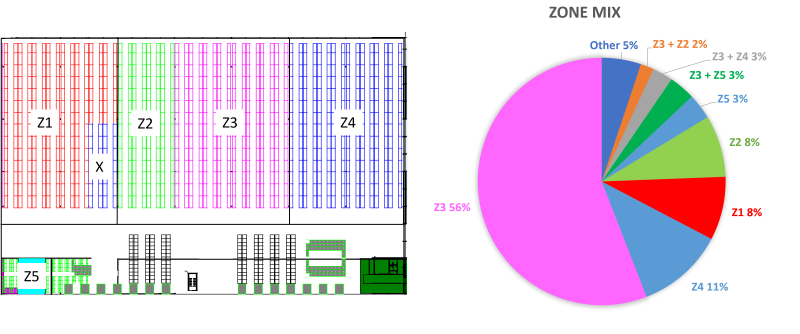

The figure above shows the layout of DC Apeldoorn with zones Z1 to Z5 that are setup by product group. Product groups include heating, plumbing, cooling, pipes and oversized. There also is a cross-dock zone (X) where items are placed that are usually not in stock. These are purchased on customer order and sent directly to customers via the cross-dock zone.

Order pickers pick the goods per zone on order-pick trucks. The Zone mix pie chart above shows from which zones the orders come. We see that 56 percent of orders come entirely from zone Z3. We see many single-zone orders also in the rest of the warehouse. All in all, no less than 88 percent of orders come from a single zone (accounting for 73 percent of the picks). This means that we only have to combine stock from multiple zones for 12 percent of orders. That is relatively little work. Order consolidation takes place at the expedition area.

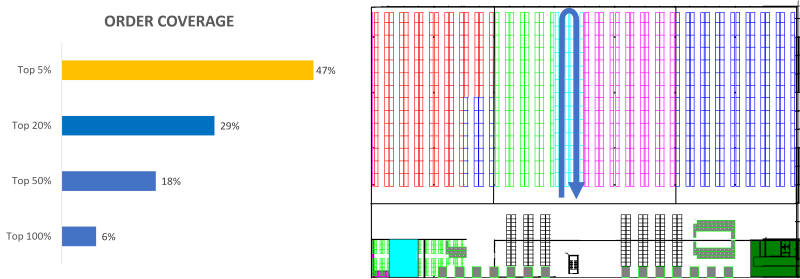

We can also deal intelligently with fast and slow movers. The graph below shows the distribution of order coverage across the assortment. This distribution is related to the well-known Pareto analysis. We sort items from fast to slow moving and then we see that we can completely cover no less than 47 percent of orders with the top 5 percent of fast moving items. Subsequently, we create a fast pick lane by placing these fast movers in the pick locations of two central aisles. For almost half of the orders it suffices to just walk up and down the fast pick lane as shown in the figure below.

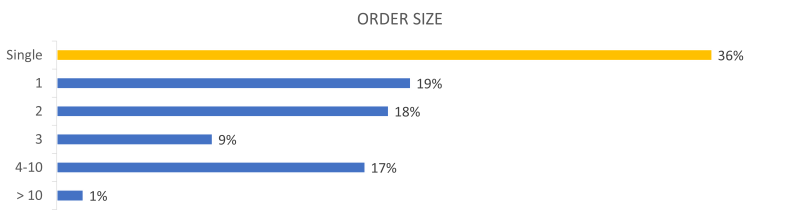

Singles

Another contemporary challenge are the increasingly smaller orders. In many web shops, 50 to 60 percent of consumer orders consist of just one single item, the so-called singles. This development is also visible in the B2B market. The order size distribution in the diagram below shows 36 percent singles in Wasco’s DC Apeldoorn. Another 19 percent of orders consist of 1 order line (with multiple pieces), while only 1 percent of orders contain more than 10 different items.

With so many small orders, it is not convenient to travel around the warehouse per order. Singles do not need to be sorted, so order pickers can easily take several orders per pick round.

It can also be interesting to collect several orders at the same time for orders with multiple order lines. The multi-order picking method allows order pickers to sort orders during their pick round on pick trolleys with multiple positions. The WMS has already calculated volumes and weights in advance, which also makes it possible to immediately place picked items in the correct shipping packages. This eliminates having orders to be packed after picking.

Solutions are readily available

Warehouse-in-warehouse and modern fine-grained picking methods are excellent examples of modern best practices. They are widely applicable, although you will have to analyze for yourself which configurations are suitable for you. The best practices are now readily available on the market. In the past, you had to take your own design to a blacksmith to have suitable trolleys welded and the WMS had to be extensively customized. That has changed.

Sorry, the comment form is closed at this time.