16 Mar Lessons Learned from the Amazon Fulfilment Center

Lessons Learned from the Amazon Fulfilment Center

I stood before the gate of the Amazon fulfilment center in Koblenz, Germany. I was about to enter the company famous for logistics innovations like picking robots, experimental drones and a private global transportation network. I wondered what to expect. I found a well-oiled machine with some unorthodox elements and learned some interesting lessons.

Entrance to fulfilment center Koblenz

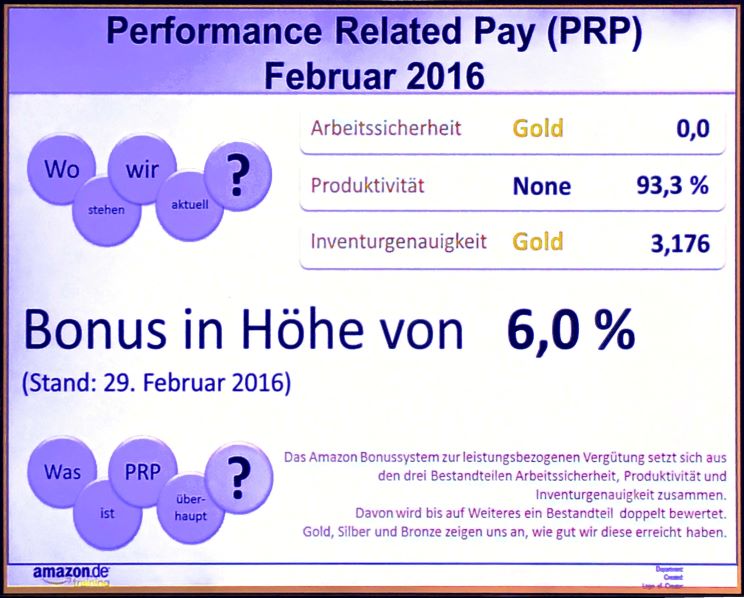

Performance bonus for safety, productivity and inventory accuracy

We entered through a tourniquet and walked up the yellow tower and over the bridge into the 110 thousand square meters building. In the lobby there a monitor with the latest KPI scores. The employees of CGN1, Amazon names fulfilment centers worldwide after the nearest airports, had earned a performance bonus of 6% in February.

20 trucks

From the lobby we walked into the fulfilment center, towards the goods receipt area. It was remarkably quiet. Despite the huge scale, only 20 trucks arrive per day, in peak season rising to approximately 40. Incoming shipments are pre-consolidated into full truckloads by logistics service providers. As such, you see many yellow semi-trailers and swap bodies with DHL imprint on the yard.

Peak Season

The fulfilment center employs 1,500 staff. Add another 1,000 in peak season. Amazon claims to hire people regardless of age or education. Our guide Andrew, a man in his sixties and active in the fulfilment center since the second month of operation, was thankful for this opportunity. The atmosphere in the workplace seemed good. People were friendly and enthusiastic and ready to help me out. It did not come across as the sweatshop that is sometimes portrayed in the media where every employee is pushed to the extreme.

No bulk stock

Large products on pallets went from the goods receipt hall directly to one of the four picking halls. This, in effect, is the first notable principle in this immense operation: there is no bulk stock! All stock is at pick locations.

Picking hall with pallets (Photo Business Insider).

Barcode number

Small items in boxes are received at the work stations. Incoming boxes contain no documents. Suppliers must indicate purchase order numbers in barcodes on shipping labels, while box contents are sent digitally to Amazon in advance. The receipt operator scans the barcode number and the warehouse management system (WMS) of Amazon knows which item to expect. The operator then scans the individual items that come out of the box and places them in yellow totes. Several different items may go into the same tote and once it is full, the operator pushes it onto a conveyor belt. If there are open orders on an item, then the system displays a message and the operator puts the item in an empty tote that leaves directly for the cross-docking zone. If there is something wrong, a yellow lamp lights up above the receiving station. The operator continues with the next item, whereas a problem-solver looks into the issue on his behalf. There also is a red lamp for acute cases.

Cubiscan

Items that come in for the first time, are brought to a special station where weights and dimensions are measured on a Cubiscan device. Results are shared globally with all fulfilment centers. Apparently, Amazon has its measures well under control, since the station was sitting idle during our entire visit.

Pick tower

The conveyor belt delivers the yellow totes to one of four floors in the pick tower. There, an operator takes the tote and distributes its contents, at his own discretion, across shelving locations. He uses a scanner for confirmation, but it gives no guidance. Amazon calls it chaotic storage, a principle that they use since 2005. An item may therefore be stored in several locations. To maintain the fill rate of the shelves, different items may be placed together in the same location.

Shelving racks in the pick tower (Photo Business Insider).

Trans-shipments

Amazon has nine fulfilment centers in Germany. Not every item, however, lies in each fulfilment center. For example, the printing on demand of books only happens in Leipzig. Amazon’s systems evaluate for each customer order which site can best supply it while taking workload and stock availability into consideration. If products for one order come from multiple sites, then the systems make a trade-off between shipping separate parcels to the customer or merging the items. The resulting shipments between Amazon fulfilment centers called trans-shipments. These arrive in black totes in the fulfilment center and are subsequently stored in a special picking area.

Amnesty

Order pickers travel around with pick carts and pick items in yellow totes for multiple orders simultaneously. Per round they pick a batch of approximately 50 items from the shelving racks. Single-piece and multi-piece orders are picked in separate rounds. With each pick, scanners display how long the pickers can do about it. After completing the pick round, they put the totes on a conveyor belt. Should they encounter items along the way that are damaged, then they put them in a damage location. Items lying around loose, they put in an amnesty location. The problem-solver then solves the matter so that pickers can always continue with their work.

Order-pickers pick items in yellow totes (Photo Wimp.com).

Robots

In the German Amazon fulfilment centers you will find no robots yet. Amazon introduced the orange Kiva robots, renamed into Amazon Robotics after the 2012 takeover by Amazon, in 2015 for the first time in Europe in a new facility in Wroclaw, Poland.

Amazon robotics (Photo Newsweek)

Wrangling

The conveyor belt delivers yellow totes with single-piece orders directly to pack stations. Totes with multi’s from different zones come together in so-called wrangling stations. Here operators sort totes by hand into batches. Given the immense scale of the fulfilment center, this is an extremely small and simple operation. Typically, warehouses have sizable intermediate buffers and sorting installations to consolidate goods from different zones. Amazon, however, manages to accurately synchronize the progress in the various zones, so that batches are ready at approximately the same time in all zones. To achieve this, Amazon’s self-made WMS needs intelligent controls. The essence of the control logic are, on the one hand, the standard times for picking that order-pickers see on their scanner screens. On the other hand, the chaotic storage plays an important role. Since a item is in several locations, the WMS can pick locations so select that the workload is evenly distributed across zones.

Re-bin station

From the wrangling station the yellow bins go on a cart per complete batch to the re-bin station. Here, items in the batch are sorted to mobile racks with a slot per customer order. If the batch is sorted, the mobile rack goes to a pack station. Here, customer orders are packed, the operator closes the parcel and attaches a small barcode label. Same as with receipt, there are no documents. The parcels move on the conveyor belt to the shipping area. Along the way, a shipping label is attached automatically. At the end of the conveyor, staff load the parcels into trolleys. The trolleys finally leave in trucks.

Year-end peak

It was clear during the tour that Amazon copes with seasonal peaks. For example, an entire hall was kept empty awaiting the year-end peak. For the same reason, several lanes with pack stations were covered under sheets.

Lessons learned

Now what were the most notable issues and what can eCommerce companies learn from Amazon?

-

- Paperless warehouse

Definitely a best practice and a clear trend. Yet many companies are not ready yet. - No bulk stock

Many companies view their fulfilment center as a storage warehouse, while they might better consider it to be a shop. I would not say that bulk stock in fulfilment centers is a bad practice, but try to limit it to items with a throughput of more than one pallet per week. - Chaotic storage

Usually, this principle is considered bad practice because of increasing search time, less compact storage and higher error rate. Still, Amazon has devised a functioning variant here. I wonder which companies will follow the example of Amazon. - Synchronized picking

By letting order pickers work in accordance with standard times and by eliminating delays, progress becomes predictable and plannable. Smart algorithms in the self-made WMS then ensure that in parallel are progressing in all areas thus combining orders is easy. Such intelligence I have not seen before in WMS. A great challenge for WMS vendors seems. - Shared inventories

The long tail plays an important role at Amazon. However, it is costly to hold every item in stock at each site. However, to prevent lost sales, stocks are shared between fulfilment centers. Now, not every company has no nine fulfilment centers, such as Amazon in Germany. Yet other companies may find opportunities to supply missing inventory from shops or directly from suppliers.

- Paperless warehouse

Postscript: We were not allowed to photograph inside the walls of the fulfilment center. Therefore I used pictures from other sources. These photos were taken in other fulfilment centers of Amazon, but are very similar to what we saw in Koblenz.

Sorry, the comment form is closed at this time.