16 Sep Smart Warehousing Weekly: What Leaders Do Differently (and What You Can Learn from Them)

In some distribution centers, everything seems to run perfectly. Deliveries are almost always flawless, the team is motivated, and there is enough flexibility to adapt to market changes. Collaboration with other departments runs smoothly, and the logistics manager has an equal seat at the table alongside sales, production, and purchasing.

In many warehouses, the reality looks very different. Performance is inconsistent, teams require constant supervision, and managers and team leaders are caught running from one incident to the next. Customer requests, delivery delays, and internal pressures all arrive at once. Meanwhile, the warehouse receives little recognition and often feels like the plaything of other departments.

Yet there is still huge potential here. The warehouse is the link that ensures both efficiency and a strong customer experience across the supply chain, upstream and downstream. Those who succeed in combining high service with low costs create an immediate competitive advantage.

But how do you find room for improvement if you spend every day putting out fires? There is no quick fix that solves everything at once. Not even the best WMS in the world will do that. Still, some distribution centers manage to run smoothly. What are their best practices – and can you adopt them? That sounds far more attractive than reinventing the wheel.

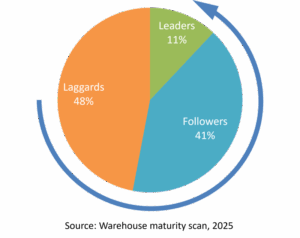

To answer that question, I collected the most important best practices in the Warehouse Maturity Scan. This online tool has now been completed more than 1,500 times by logistics professionals. In addition to analyses and tips, the tool provides a maturity score for warehouses, expressed as a percentage between 0 and 100. Based on that score, warehouses can be divided into three categories:

-

>67% → Leaders: Apply more than two-thirds of best practices

-

33–67% → Followers: Apply one-third to two-thirds

-

<33% → Laggards: Apply less than one-third

The scans show that, on average, out of ten warehouses only one is a leader, four are followers, and five are laggards (see image).

In this blog series Smart Warehousing Weekly, I’ll explore the secrets of those leaders – and how you can apply them in your own warehouse. Share your experiences, whether you are a leader, follower, or laggard. That’s how we help each other reach the top.

Sorry, the comment form is closed at this time.